About FlexiForm

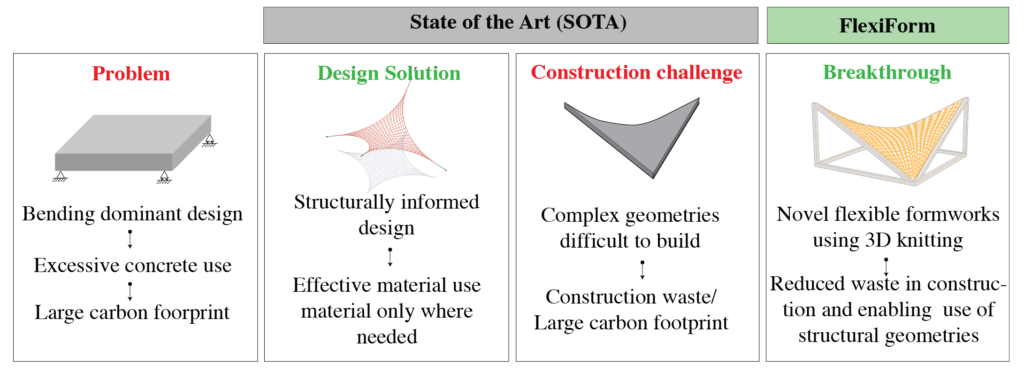

The FlexiForm project is set to transform the construction industry by substantially reducing material usage and embodied carbon in new buildings through an innovative design and construction approach for concrete structures. By leveraging the structural and material efficiency of double-curved geometries and lightweight 3D knitted textile formworks, the project seeks to create sustainable, cost-effective, and reliable structural solutions. To achieve this challenging goal, the project will develop a unified computational design and fabrication workflow that optimizes material usage and accurately predicts the mechanical properties of knitted textiles. By incorporating knitted textiles material and fabrication constraints into the workflow, the project will reduce reliance on specialized knowledge and physical testing. Moreover, the FlexiForm project will establish an open- source material database and a form-finding method for knitted textile formworks that will facilitate the widespread adoption of sustainable practices in the construction industry. Ultimately, the project’s outcomes will contribute to the objectives of the European Green Deal and the New European Bauhaus, promoting transparency, collaboration, and dissemination of research findings. Through reducing raw material consumption and introducing innovative construction techniques, the FlexiForm project will pave the way for a more sustainable and efficient future in the construction industry.

Project Objectives

Reduce material use and embodied carbon in the construction industry by promoting the design and construction of concrete structures that minimise the use of concrete and decrease the reliance on disposable formwork during construction. To achieve this goal, the project will focus on two interconnected strategies:

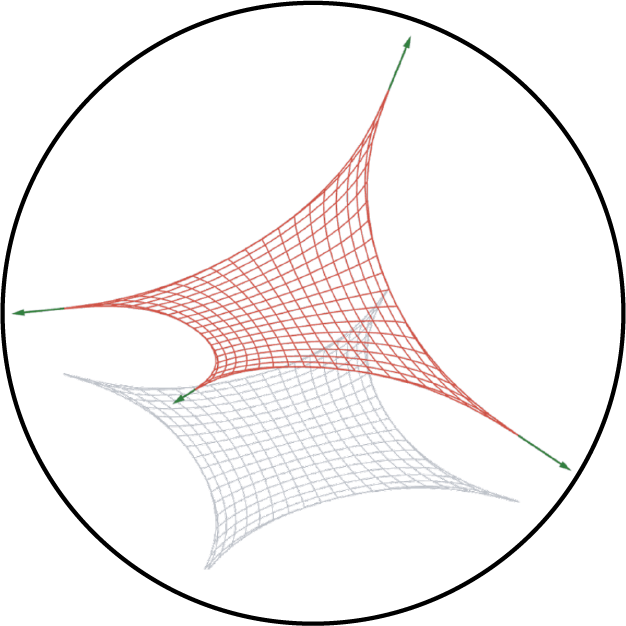

- (a) leverage the structural and material efficiency of double-curved concrete structures and

- (b) capitalise on the flexibility of lightweight textile formworks to simplify and expedite construction, while enhancing safety, even in existing built contexts.

Technological breakthroughs

computational form-finding for the structural design of knitted formworks

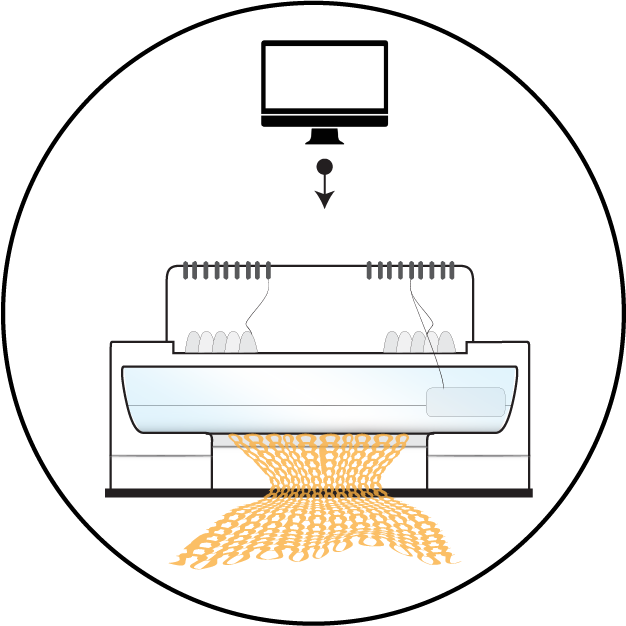

digital fabrication techniques using knitted formworks

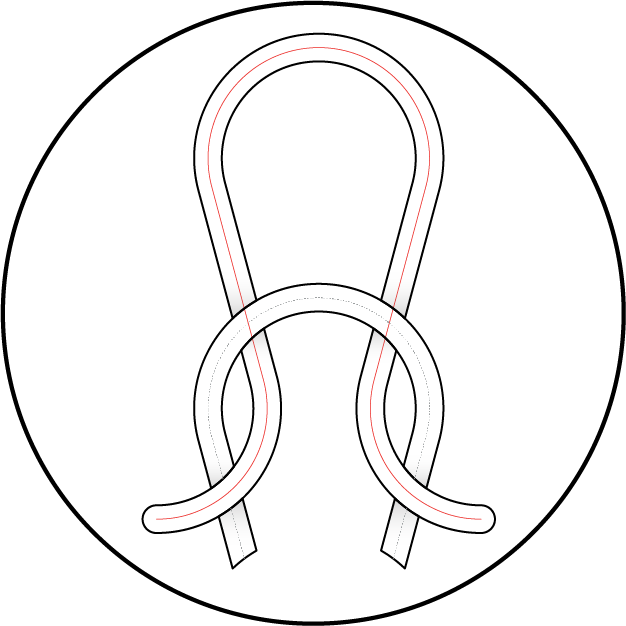

design and analysis of knitted materials

By incorporating fabrication constraints, considering material-efficient structures, and accurately predicting material behaviour, the project will enable the creation of optimised structural designs that can be efficiently fabricated using knitted textile formworks.

Methods and Work Packages

WP1 – Project Management

WP1 focuses on ensuring successful project execution through effective communication, timely goal achievement, and adherence to budget constraints. This involves maintaining open channels of communication among project partners, compiling and submitting technical reports, and facilitating smooth interactions with the European Commission and Project Officer.

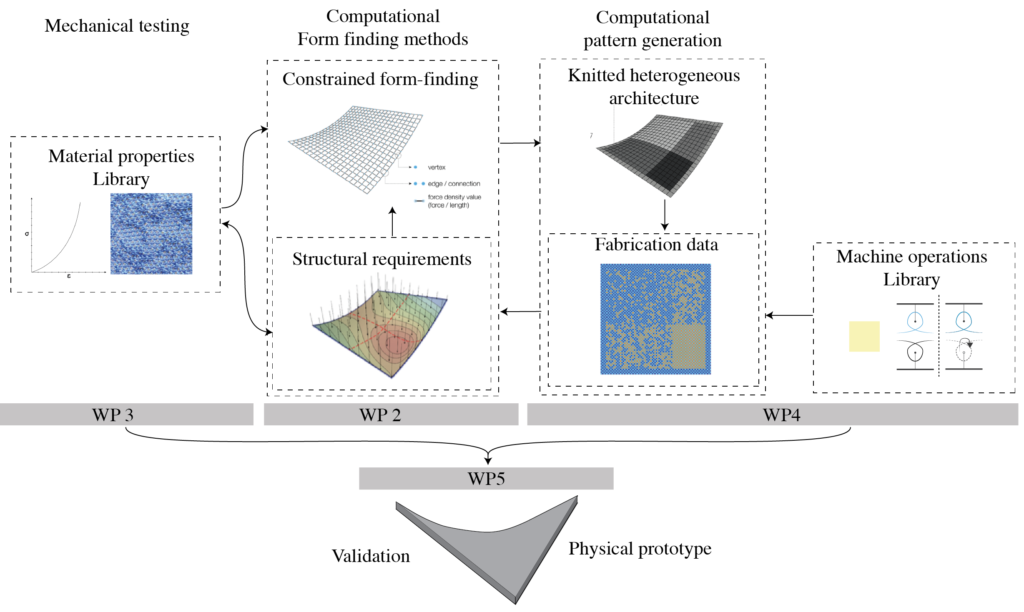

WP2 – Material Design

WP2 investigates the material properties and behaviour of various knitted textiles. It focuses on two main objectives. Firstly, we will determine the material properties of different knitted textiles through extensive testing and analysis. Secondly, we will develop models to accurately represent the material behaviour of meso-scale knitted architectures. These models will be designed to integrate seamlessly with the form-finding methods established in Work Package 4 (WP4).

WP3 – Digital Fabrication

WP3 focuses on developing fabrication methods for knitted textiles. This work package will develop fabrication pipelines for knitted textiles that incorporate material properties and design considerations. It seeks to incorporate material properties into the knitting pattern generation process, thus establishing efficient and effective methods for producing knitted textiles with desired properties and designs. This work package will build upon the findings from WP2, ensuring that the fabrication processes are informed by the material properties and behaviour of knitted textiles.

WP4 – Computational Structural design

WP4 focuses on developing computational form-finding methods for knitted textile formworks. This work package aims to formulate a comprehensive approach for designing these formworks, taking into account the unique properties of knitted textiles. Additionally, the work package will adapt the form-finding method to incorporate the effects of concrete’s self-weight during the construction process.

WP5 – Implementation Case-Study

WP5 focuses on validating and demonstrating the proposed workflow for flexible formworks. This work package aims to build a full-scale prototype using the design and fabrication workflow developed for flexible formworks. Through this prototype, we will demonstrate the effectiveness of flexible formwork technology in real-world applications. Additionally, WP5 will emphasize knowledge transfer to promote industry adoption of the developed technology. By showcasing the practical implementation and benefits of our research, we aim to bridge the gap between academic findings and industrial applications, encouraging wider adoption of flexible formwork technology in construction practices.

WP6 – Portfolio Management

WP6 aims at exploring synergies and collaborations among the projects of the portfolio, to maximize the achievement of the scientific results, the exploitation potentials, the outreach opportunities with key stakeholders, the identification and overcoming of major barriers to introduce novel technologies to the architecture engineering construction industry.

Portfolio projects will be expected to exchange information on the results achieved within their projects, their research methodologies, experimental tests, techno-economic input data in order to explore synergies and achieve more impact than one single project can achieve. The exchange of information for the purpose of EIC portfolio activities will fall under the conditions and non-disclosure obligations as specified in the EIC Work Programme 2023 (Annex 6, section 2.2).

WP7 – Communication, Dissemination and Innovation

WP7 focuses on communication and dissemination of the project’s outcomes. This work package aims to effectively communicate the scope, goals, and main findings of the project to various target groups. It will ensure that project results are disseminated through scientific publications and technical reports, making the research findings accessible to the academic community and industry professionals. Additionally, WP7 will facilitate engagement with representatives of the Architecture, Engineering, and Construction (AEC) sector to develop strategies for technology transfer. This approach will help bridge the gap between research and practical applications, promoting the adoption of the project’s innovations in real-world scenarios.

Partnership

FlexiForm | Project is funded by the European Union | Programme: HORIZON – EIC | Project ID: 101162376 | Call: HORIZON-EIC-2023-PATHFINDERCHALLENGES-01